Lightweighting Strategies for Electric Vehicles

Electric vehicles (EVs) continue to evolve at a rapid pace, driven by rising range expectations, efficiency demands, and aggressive sustainability goals. As manufacturers work to extend battery performance without compromising safety or durability, lightweighting has become a core engineering strategy. From body panels to glazing systems, advanced materials and optimized components help EV platforms maintain structural integrity while reducing mass and improving efficiency.

This article explores what lightweighting means for the modern EV, and how Five Star Fabricating’s advanced polycarbonate windows, Fusionite™ coatings, and high-strength composite solutions help OEMs achieve lighter, stronger, and higher-performing vehicles.

What Is Lightweighting in Electric Vehicles?

Lightweighting is the strategic reduction of vehicle mass using advanced materials, precision design, and optimized manufacturing. Because EVs carry heavy battery systems, even modest weight reductions can dramatically influence efficiency, range, suspension load, and overall performance.

Lightweighting focuses on:

- Reducing mass while maintaining or improving durability

- Using materials with high strength-to-weight performance

- Enhancing aerodynamics and efficiency

- Maximizing battery performance and extending range

In EVs, every pound saved contributes to longer range, lower energy consumption, improved handling, and reduced wear on mechanical systems.

Key Components or Types of Lightweighting Strategies

- Body Panels & Structural Components – Carbon fiber and advanced composites replace steel for significant mass reduction.

- Glazing & Window Systems – Polycarbonate windows are typically 40–60% lighter than glass.

- Interior & Exterior Plastics – Thermoformed plastics reduce weight in housings, covers, and aerodynamic features.

- Integrated Coatings & Surface Technologies – Maintain clarity, reduce maintenance, and extend service life.

- Streamlined Assembly – Use of thinner, stronger, or multi-functional parts to cut redundant materials.

Why Lightweighting Matters for EVs

Because battery packs account for a major portion of EV weight, non-battery components must be as light as possible. Lightweighting directly impacts:

- Range Extension – Less mass means lower energy consumption.

- Performance – Better acceleration, handling, and brake responsiveness.

- Durability – Reduced strain on hinges, frames, and mounting points.

- Sustainability – Lower material use and improved efficiency reduce environmental impact.

- Cost Savings – Lower operating costs due to reduced wear and energy consumption.

Specific Benefits of Lightweighting Strategies

- Up to 70% weight reduction using advanced composites versus steel

- 40–60% lighter window systems using polycarbonate instead of glass

- Improved clarity and safety through scratch-resistant coatings

- Longer component lifespan, reducing service and replacement frequency

- Enhanced aerodynamics through formable, lightweight plastics

These benefits make lightweighting an essential pillar of modern EV engineering.

How Lightweighting Enhances EV Efficiency and Range

Reducing mass in strategic areas directly impacts battery load and driveline resistance. When windows, body panels, and structural components are redesigned with high-performance materials, EVs experience:

- Lower rolling resistance

- Reduced aerodynamic drag with optimized glazing curvature

- Higher battery efficiency, especially in city-driving conditions

- Improved safety with impact-resistant materials

The result is measurable improvement in range, charge efficiency, durability, and overall longevity.

Key Ways Lightweighting Delivers Value

- Advanced Composites cut mass without sacrificing strength.

- Polycarbonate glazing reduces weight while improving safety and clarity.

- Fusionite™ coatings extend component life in all weather cycles.

- Thermoformed plastics replace heavier metal or glass components.

- Integrated design reduces part counts and streamlines assembly.

Five Star Fabricating’s Role in EV Lightweighting

Five Star Fabricating delivers end-to-end lightweighting solutions designed specifically for high-performance, durability-critical vehicles, including emerging EV platforms. With more than 47 years of experience and vertically integrated manufacturing, our team engineers components that reduce mass while increasing impact strength, optical clarity, and environmental durability.

Their EV-aligned offerings include:

- Polycarbonate performance windows

- Fusionite™ abrasion-resistant and UV-stable coatings

- Advanced carbon fiber composites

- Thermoformed polycarbonate plastics

- Rapid prototyping and engineering support

Five Star’s Contributions to Lightweighting for EVs

- Performance Polycarbonate Windows

Up to 40–60% lighter than glass, our EV-ready polycarbonate windows deliver:

- High impact resistance (orders of magnitude over glass at comparable thickness; see test notes)

- Optical clarity with minimal distortion

- Large-format forming up to 8 × 11 ft

- Custom thicknesses (0.010–0.500 in)

- CNC-machined edges, countersunk hardware, and tight-tolerance assembly

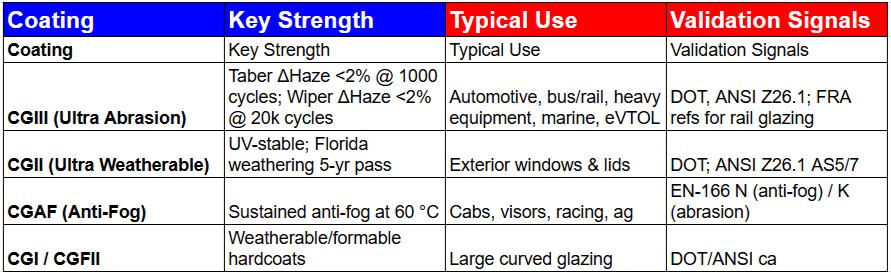

- Fusionite™ Coatings

A core differentiator engineered for durability and lifecycle performance:

- Taber abrasion results under 2% haze (typical; per ASTM D1044; verify against current data sheet)

- UV-stable formulations for long-term outdoor exposure

- Anti-fog, anti-glare, and chemical-resistant stacks

- Formable options for complex EV glazing geometries

- Automotive AS1/AS2 compliance (confirm by part and use case)

- Advanced Composites

Carbon fiber solutions with up to 70% weight savings, enabling lightweight EV:

- Body panels

- Underbody aerodynamic panels

- Charging-system housings

- Structural reinforcements

- Thermoformed Plastics

Used for interior and exterior covers, aerodynamic elements, housings, and protective shields—all engineered for lightweight performance.

Broader Impacts of Lightweight EV Components

Lightweighting extends beyond engineering; it reshapes environmental, operational, and economic outcomes.

Environmental Impact

- Lower energy consumption per mile

- Reduced greenhouse gas emissions

- Longer-lasting components minimizing waste

- Improved recyclability through single-material design opportunities

Operational & Economic Impact

- Reduced maintenance from durable hardcoated windows

- Improved operator visibility and safety

- Lower total cost of ownership

- Extended service intervals and fewer part replacements

Five Star’s coated polycarbonate windows and advanced composites significantly enhance these lifecycle advantages.

Future Trends in EV Lightweighting

Lightweighting will only grow more essential as EV ranges climb and design complexity increases.

Key Trends to Watch

- Larger curved polycarbonate windshields for aerodynamic optimization

- Hybrid laminated polycarbonate structures for impact/ballistic resistance

- Integrated coatings combining abrasion, UV, fog, IR/heat control

- Multi-functional composite structures replacing multi-part assemblies

- Next-generation recyclability programs aligning with OEM ESG goals

Five Star Fabricating is strategically positioned with advanced forming, coating, and composite technologies to support emerging EV innovations.

Frequently Asked Questions

Why is lightweighting important for EVs?

Reducing mass improves range, efficiency, battery life, and overall vehicle performance.

How much weight can polycarbonate windows save?

Up to 40–60% compared with glass, depending on design.

Are polycarbonate windows durable enough for EV use?

Yes. Fusionite™-coated polycarbonate delivers superior impact strength and long-term clarity.

What materials are most effective for EV lightweighting?

Polycarbonate glazing, carbon fiber composites, and thermoformed plastics provide the most significant mass reduction without sacrificing durability.

Design & Test Notes (Quick)

- Abrasion: ASTM D1044 (Taber) haze increase. Verify current spec sheet values.

- Impact/Strength: Polycarbonate vs. tempered glass comparisons are test-dependent (for example ASTM D256 and IZOD/Charpy).

- Optical/Glazing: Automotive glass markings AS1/AS2. Applicability depends on part type and regulations.

- Dimensions: Large-format forming up to 8 × 11 ft varies by geometry, thickness, and tooling.

For exact values, consult Five Star’s current data sheets or speak with engineering.

Build Lighter, Stronger EVs with Five Star Fabricating

Lightweighting is essential to the future of electric mobility, and Five Star Fabricating delivers the materials and technologies that help OEMs achieve it. From coated polycarbonate windows to advanced composites and thermoformed plastics, Five Star provides high-performance, production-ready solutions that reduce weight, extend range, and increase durability.

Ready to engineer next-generation lightweight EV components?