Carl Schultz

President and Chief Executive Officer

Welcome to Five Star Fabricating

Five Star is the industry leading manufacturer of American-made advanced composites, polycarbonate windows, and thermoformed plastics. Our technologies are born from the tight-tolerance, high performance world of auto racing, making us the leader in developing lighter and stronger automotive exterior components. Our company was founded in 1978 on the principle that quality must be the highest priority – both for our company's success and for the benefit and integrity of an entire industry. The fact that you have come to us here shows that your commitment to developing high-quality fabricated components is every bit as strong as our own.

From the Track to the Factory Floor

Our story started when Fran Prestay, owner of a local auto service shop, asked Carl Schultz—who ran a plumbing and heating business across the street—to fabricate sheet metal fenders for his short-track race car. After a rough night at the track and struggling to find quality parts in the salvage yard, Fran needed a better solution. Carl delivered.

The custom fenders were a hit, and word spread fast. What began as a favor turned into a business opportunity. In 1978, the duo founded Five Star Fabricating, and by 1979 they were producing body components for the Camaro. A small ad in Stock Car Racing Magazine and a flood of word-of-mouth interest quickly elevated the company into national recognition.

Driven by Innovation

From those first hand-formed sheet metal parts, Five Star quickly evolved into producing thermoformed plastics, hand-laid fiberglass, and advanced composite body panels. These materials helped us lead the racing industry in producing durable, lightweight parts with structural integrity and elite visual finish.

Along the way, we perfected the art of polycarbonate windows. Our engineers created proprietary coatings and materials that elevated window strength, clarity, and durability—leading to the development of the most trusted racing windows in the world. Today, Five Star windows are #1 in all of motorsports.

Beyond Racing: Engineering for Every Industry

Over the past 47 years, the quality demands of motorsports have shaped our manufacturing culture—pushing us to continually expand our in-house capabilities. That experience now powers our ability to partner with companies far beyond racing.

Our facilities and engineering teams deliver best-in-class fabricated components that are lightweight, high-strength, defect-free, and performance-validated. From concept to production, we walk with our customers through every stage of development.

We’re proud to bring motorsports-grade technology into new markets—supporting OEM, transportation, defense, heavy equipment, and aerospace programs with custom polycarbonate and composite solutions.

Built to Perform. Built to Last.

Our team of 250+ employees operates out of more than 350,000 square feet of modern manufacturing space across six specialized facilities. Every part that leaves our doors is built on the values we were founded on: quality, innovation, customer focus, and resilience.

Whether you need impact-resistant windows, thermoformed components, or advanced composites for mission-critical applications, we’re ready to deliver. At Five Star Fabricating, our goal is simple: build it stronger, smarter, and faster—every time.

Our Commitment to American Manufacturing

At Five Star, we don’t just build parts — we support programs. Whether you’re launching a high-performance OEM component or scaling a custom retrofit system, our manufacturing approach is engineered to move as fast and as precise as you need.

Our cross-trained production teams and vertically integrated operation allow us to scale without sacrificing fit, finish, or delivery. From concept to full-volume production, we support your internal deadlines, engineering validation, and customer expectations with real-world speed and a proven commitment to quality.

Our Philosophy: Values That Power Performance

Five Star employees and their welfare are very important to the success of our company. Every employee is considered a member of our company team. Our success as a company is built on the recognition of the skills and efforts made by each employee. It is our policy to work with all members of our team in a fair and friendly manner and to treat each team member with dignity and respect. As a family-owned and operated business, we use the values of the Schultz Family as a guiding philosophy for running the business. These values are as follows:

Our Core Values

INNOVATION

Progress, pushing boundaries, and creating groundbreaking solutions that shape the future.

WINNING

Resilience, determination, propelling individuals to overcome challenges and achieve their goals.

DEDICATION

Fueling individuals to put in the necessary effort and perseverance to succeed.

CUSTOMER FOCUS

Understanding and fulfilling the needs and expectations of customers.

EXCELLENCE

Surpassing ordinary standards, constantly striving for the highest level of quality, innovation, and achievement.

We are committed to these values and they are reflected in every area of our lives and how we do business. The adoption of these core values is essential to executing our strategy and ensuring a work environment that supports The Company’s objectives and inspires employees to new levels of productivity, helping them achieve their professional goals. We are confident in our ability to execute on our strategies making Five Star a fun, rewarding place to work.

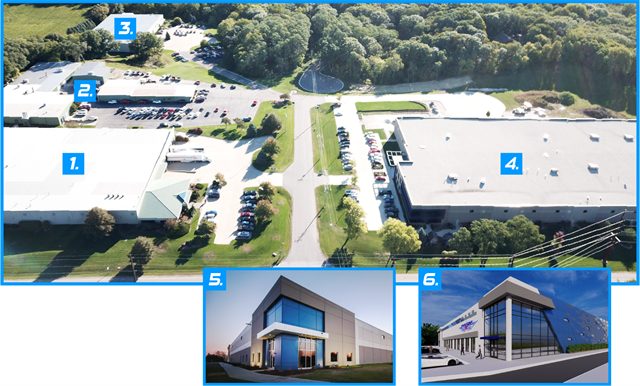

State-of-the-Art Facilities

Five Star has expanded 14 times since 1986, operating out of 300,000+ SF of clean, modern manufacturing and distribution space in (3) locations, totaling 34 acres.

1. Finished Goods & Plastic Forming

Twin Lakes, WI

2. Composite Tooling & Design

Twin Lakes, WI

3. Composite Production

Twin Lakes, WI

4. Window Coating & Forming

Twin Lakes, WI

5. Tooling Storage Facility

Trevor, WI

6. Dealer Service Center

Concord, NC

On-site Testing Laboratory

The research and development laboratory at Five Star demonstrates our dedication to improving quality and creates an environment for our engineering teams to seek new discoveries and accelerate product innovation for our customers. Five Star utilizes an extensive array of tools and equipment to support its engineering, testing, and quality control processes. We employ various testing measures in accordance with ASTM International standards to test the following:

- Flex & load/deflection behavior

- Cosmetic purity

- UV degradation

- Impact resistance

- Chemical resistance

- Heat resistance

- Ink and paint adhesion

- Optical clarity

- Light transmission

- Flex & load/deflection behavior

- Compression, tensile, & shear strength

These testing measures are helpful in guiding our customers to the proper materials and processes to achieve the highest quality composite, polycarbonate, or thermoformed plastic part.

Five Star Quality Policy

Five Star has maintained a Quality Management System certified to the ISO 9001 standard since August, 2014.

This certification has proven to be an important step in assuring that customers receive the very best in quality

and service.

Five Star Team Members will strive to:

- Meet customer and regulatory requirements

- Continuously improve the QMS;

- Meet company growth goals;

- Maintain a clean and safe workplace while protecting the environment we live in.

We accomplish our commitments by:

- Customer Satisfaction:

• Monitor monthly and act to keep customers satisfied with product quality and on-time deliveries. - Scrap as a percent of Produced:

• Monitor weekly and work to keep scrap below a cumulative monthly average of 4.5%. - Continuous Improvements:

• Work to implement 100 or more improvements in products and/or processes per year companywide. - Training & Education:

• Maintain Training Programs to ensure employee competence/annual target of 6,800 hours. - Safe Working Environment:

• Conduct monthly Housekeeping-Safety Audits and act to ensure 7 or less reportable injuries per year. - Company Growth:

• Monitor monthly and work to maintain a flat to upward trend in Company Sales.

What Our Employees Say

You walk in our building and you’ll see nobody has closed doors to their offices. Titles are not a big deal here. It’s about working together as a team and solving problems and issues as quickly as we possibly can.

Mike Schuppert, Vice President

I’ve been in factories around the world and rarely have I seen an operation as clean, well lit, and orderly as the Five Star facilities. The top-notch appearance of the facilities reflects the company’s attention to detail and our commitment to quality.

Doug Manternach, Director of Product Development

STATE-OF-THE-ART FACTORY

HIGH QUALITY TOOLING

FAST & RESPONSIVE SERVICE

DESIGN COLLABORATION

LARGE VOLUME PRODUCTION