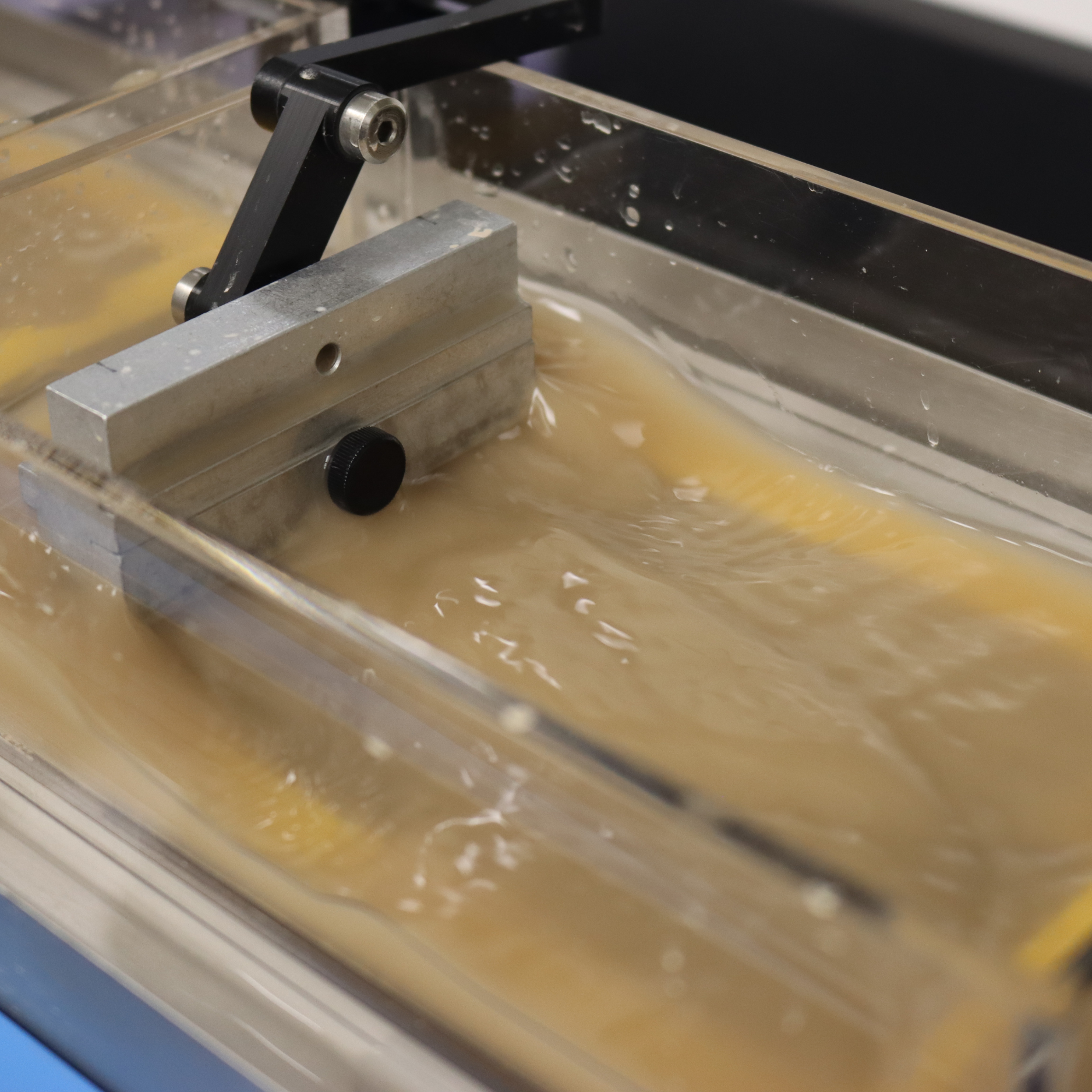

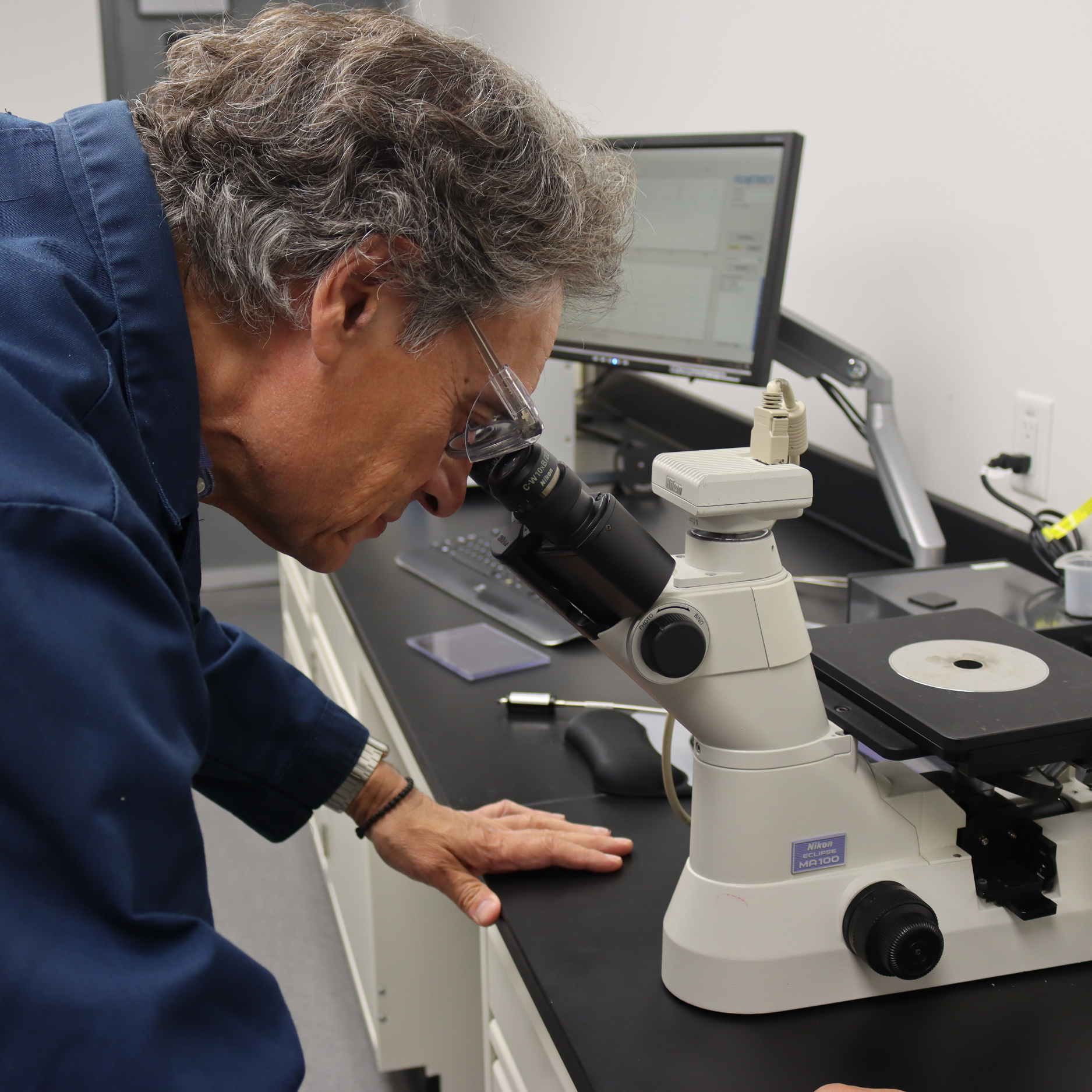

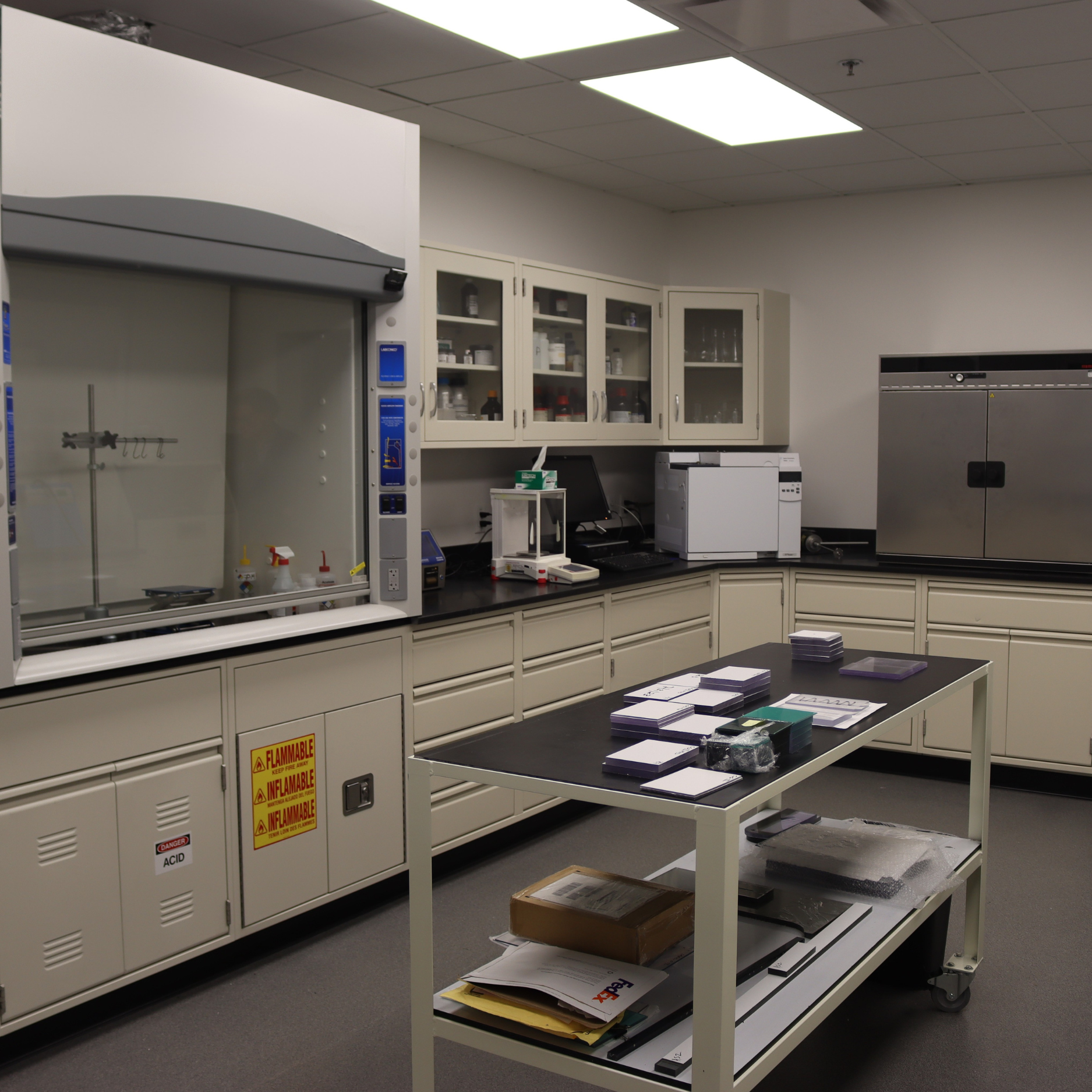

At Five Star Fabricating, we don’t just manufacture — we validate. Our in-house laboratory is a critical part of our commitment to quality, innovation, and customer success. We provide fast, reliable testing services to support production quality control, coatings development, and product validation.

Lab Testing Capabilities

| Test Category | Test Capability | Relevant Standards |

|---|---|---|

| Adhesion Testing | Cross Hatch Adhesion 180° Peel Adhesion |

ASTM D3359, ISO 2409 ASTM D3330, ASTM F88 |

| Optical Quality & Appearance | Light Transmission & Haze Measurement Gloss Measurement Visual Optical Distortion Evaluation |

ASTM D1003, ISO 13468-1 ASTM D523 ISO 3538-2, SAE J1757 |

| Abrasion & Wear Resistance | Scrub Resistance / Washability Taber Rotary Abrasion Falling Sand Abrasion |

ISO 11998, ECE R43 ASTM D1044 ASTM D968 |

| Environmental Durability | Water Immersion Resistance Heat Aging (Oven Exposure) Humidity Resistance Chemical Resistance |

ASTM D870 ASTM D3045 ASTM D2247 ASTM D1308, ISO 2812 |

| Electrical Properties | Surface Resistivity Insulation Resistance |

ASTM D257, IEC 60093 ASTM D257 |

| Impact Resistance | Projectile & Multiaxial Impact Testing | ASTM F22, ISO 6603-2, SAE J1615, FMVSS 205 S5.3, ISO 3537 Internal Cannon & Ball Drop Testing |

| Material Characterization | Viscosity Measurements (Ford Dip Cup) Gas Chromatography / Solvent Content Coating Thickness Measurement (Filmetrics) Microscopy Analysis / Optical Defect Characterization |

ASTM D1200, ASTM D4212 ASTM D6730 ASTM D7091 |

| Additional Partner Lab Testing | Weathering Stone Impact Cross-Section & Coating Thickness Burn Resistance |

ASTM G154, SAE J2020, SAE J400 ASTM D3170, ASTM D4138, ASTM D1005 FMVSS 302, SFI 56.1 |

Why It Matters

Our in-house lab capabilities allow us to quickly validate and support the performance of our coated polycarbonate glazing and composite products. To complement our in-house services, we maintain partnerships with trusted, accredited third-party laboratories to provide additional testing services. This enables us to offer a complete validation solution aligned with the most common OEM, ASTM, ISO, and SAE requirements.