Electrification, lightweighting, and sustainability have shifted from trend lines to hard requirements. Procurement leaders, design engineers, and supply-chain executives now measure success by how quickly they can remove vehicle mass, cut lifecycle cost, and meet tightening environmental rules—without sacrificing reliability or optical performance in high-visibility parts like windows and exterior panels. This pillar guide maps the forces reshaping automotive manufacturing and, crucially, shows how Five Star Fabricating helps OEM suppliers hit these targets with polycarbonate performance windows, Fusionite™ coatings, and thermoformed panels backed by vertically integrated manufacturing and on-site validation.

What Is “Driving the Future” in Automotive Manufacturing?

Electrification, sustainable materials, and cost discipline are converging in the next product cycle. In practice, that means:

- Electrification & Lightweighting: Every kilogram matters for range, payload, and energy efficiency. Glazing is a prime opportunity: polycarbonate windows can replace heavier glass while maintaining optical clarity and safety when paired with the right coating stack.

Sustainable Materials: Durable, recyclable substrates and coatings that extend service life reduce replacements, waste, and transport emissions directly supporting OEMs’ circularity and recycled-content goals. - Cost Discipline & Speed: Partners who prototype fast, validate in-house, and scale cleanly across platforms minimize risk and shorten time-to-SOP. Five Star’s integrated forming, coating, CNC, assembly, and lab testing compress this path.

Bottom line: “Driving the future” is less about a single technology and more about orchestrating materials, coatings, and processes to achieve durability, usability, and performance at costand proving it with data.

Key Components or Types Shaping This Shift

- Performance Polycarbonate Windows: Engineered for high impact strength (≈200–250× stronger than glass) with significant weight reduction versus glass, validated to automotive and transit standards (USDOT, ANSI Z26.1, FMVSS 217a, ECE R43).

- Fusionite™ Coatings: Abrasion resistance (Taber ΔHaze often <2%), UV stability, chemical resistance, and anti-fog options; applied to flat or complex 3D surfaces up to ~8 × 11 ft.

- Thermoformed Plastics & Advanced Composites: Vacuum or pressure-formed panels (0.010–0.500 in) and carbon-fiber components that unlock styling complexity and deep mass savings on body and enclosure parts.

Why It Matters

EV adoption is rising, hybrids are bridging gaps where subsidies slow BEV uptake, and regulators are advancing recycled-content and circularity frameworks. Lightweighting is the common denominator, especially in glazing, where polycarbonate with appropriate hardcoats maintains clarity and durability under harsh duty cycles. Mass reductions in glazing can improve EV range and reduce fuel use on ICE platforms. Operators also benefit from lighter doors and windshields, which reduce hinge loads and simplify service.

At the same time, cost pressure is intensifying. Programs require faster prototyping, cleaner PPAP documentation, and fewer late-stage surprises. A vertically integrated supplier that can design, form, coat, finish, test, and assemble under one roof reduces hand-offs and scrap—two reliable levers for cost and timing control. Five Star’s ISO 9001:2015 quality system and on-site lab (adhesion, optical, abrasion, environmental, impact) give OEM teams a single accountable source for validation.

Ready to optimize your glazing for lighter weight, lower costs, and longer life? Contact Five Star today for a free consultation on integrated solutions tailored to your program needs.

How Lightweight Glazing Enhances EV & ICE Platforms

Mechanisms that move the needle

- Mass reduction: Polycarbonate glazing typically achieves ~40–60% weight savings vs. glass (design-dependent). Lighter windows improve energy efficiency/range, reduce load on hinges and lifts, as well as giving ease on installation and service.

- Impact performance: Polycarbonate is ≈200–250× stronger than glass, resisting crack-outs from debris, stone strikes, and tools. Laminated stacks can add ballistic or enhanced impact performance where needed.

- Optical durability: With the right hardcoat, ΔHaze remains low after severe Taber and wiper abrasion; anti-fog formulations maintain visibility in humidity and temperature swings.

Typical outcomes

- Fewer break or fog replacements → lower downtime and lower lifecycle cost.

- Lighter door or windshield systems → better ergonomics and longer hardware life.

Stabilized clarity over time → safer operators and higher productivity.

Five Star’s Performance Windows & Fusionite™ Coatings (The Core Solution)

Five Star’s glazing systems unite material science, precision forming, and coatings engineering into a durable, lightweight package built for automotive, transit, and specialty vehicles.

What sets our windows apart

- Materials & forming: Optical-grade polycarbonate is formed by drape, vacuum, or pressure processes for large, complex curves, then CNC-finished (3/5/6-axis) for precise fit, including beveled edges, countersunk holes, and printed frits.

- Coating stacks: Fusionite™ families deliver abrasion resistance (Taber ΔHaze targets often <2%), UV stability, chemical resistance, and anti-fog performance; specialized systems address wiper abrasion and even IR/heat management.

- Scale & size: Coatings applied to flat or complex surfaces up to ~8 × 11 ft, supporting bus/rail windshields, large curved EV glazing, and specialty vehicle cabs.

- Speed & documentation: Prototypes in as little as two weeks, with PPAP/PFMEA under an ISO 9001 QMS; on-site lab validation de-risks launch.

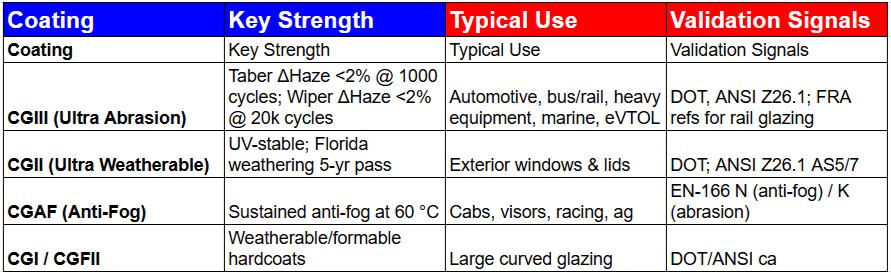

Representative Fusionite™ options (illustrative)

Many programs also integrate printed frits for UV edge protection, laser etching for part IDs, and laminated interlayers (e.g., PVB) for additional impact absorption.

Thermoformed Plastics & Advanced Composites (Complementary Lightweighting)

While glazing carries huge efficiency and uptime wins, exterior/interior panels and enclosures often determine whether a platform hits styling, mass, and cost goals.

- Thermoformed plastics: Vacuum/pressure forming enables large parts with crisp details and textures, ideal for bezels, fairings, interior shells, and exterior covers—especially where small/medium runs make injection molding uneconomical. Typical thickness: 0.010–0.500 in.

- Advanced composites: Carbon fiber delivers up to ~70% weight reduction vs. steel with high stiffness-to-weight and is well suited for structural panels and aero surfaces that complement lightweight glazing.

Why This Matters to OEM Suppliers (Durability • Usability • Performance)

- Durability: Impact strength helps resist crack-outs and unscheduled maintenance. Hardcoats slow haze growth under dust and wipers, keeping sightlines stable longer.

- Usability: Lower mass means easier installation, less strain on hinges and lifts, and improved ergonomics for service teams.

- Performance: Aerodynamic and visual design freedom via drape or pressure forming enables panoramic visibility and signature curves. Large-format capability reduces seams for cleaner sightlines and fewer leak paths.

How Five Star Enhances Electrification, Sustainability, and Cost Savings

Electrification: Lightweighting that multiplies value

- Energy efficiency/range: Replacing glass with polycarbonate glazing saves ~40–60% mass (design-dependent), a direct contributor to range in BEVs and fuel savings in ICE/hybrid fleets.

- Reliability in high-torque duty cycles: Impact-resistant windows reduce crack-outs from launch torque vibrations and road debris, supporting uptime for delivery, shuttle, and specialty EVs.

Thermal management options: Coating stacks can incorporate IR/UV control to reduce cabin heat load, valuable in EV cabs where HVAC impacts range.

Sustainable materials: Longevity and circularity, not just “recycled”

- Long-life coatings reduce replacement frequency, cutting material and logistics emissions over the vehicle life.

- Recyclable substrates with removable functional coatings support practical end-of-life pathways.

- Transit & commercial fleets: Weight cuts of up to ~30% on glazing systems in mass transit translate to lower energy consumption and emissions.

Cost savings: Speed, scale, and documentation

- Rapid prototypes (≈2 weeks) and on-site testing shrink loops between design intent and validated parts, reducing late ECOs and scrap.

PPAP/PFMEA under ISO 9001 simplifies supplier quality audits and platform reuse. - Large-format capability (oversized ovens/molds/CNC; coatings to ~8 × 11 ft) consolidates parts and seams, reducing assembly time and leak-path risk.

Five Star’s Role in Automotive Programs (What You Can Expect)

Facilities & Integration

Five Star operates ~350,000 sq ft across multiple specialized buildings, integrating forming, coating, CNC machining (3/5/6-axis), assembly, and an on-site lab for adhesion/optical/abrasion/environmental/impact testing. The company’s ISO 9001:2015 certificate (effective through 2027) covers manufacturing of composite, polycarbonate, and plastic components plus coating design/application.

Engagement Flow

- NDA & CAD intake with duty-cycle requirements (dust, wiper cycles, chemicals, UV/weathering).

- Coating stack selection (abrasion class, anti-fog, UV, IR, chemical resistance).

- Prototype (often in ≈2 weeks) → on-site lab validation (optics, Taber, wiper, environmental).

- PPAP/PFMEA and production ramp with documented process controls.

Compliance & Standards

Windows and panels are designed toward USDOT, ANSI Z26.1, FMVSS 217a, and ECE R43 where applicable, with aerospace programs guided by AS9100.

Broader Impacts: Operational, Environmental, Economic

Operational: Impact-resistant glazing lowers unplanned service events and keeps machines available. Abrasion-resistant hardcoats maintain optical clarity longer under dust, sand, salt, and heavy wiper usage, directly improving safety and operator confidence.

Environmental: Fewer replacements and lighter vehicles reduce materials usage and transport emissions over the lifecycle. In mass transit, glazing weight reduction alone can improve fuel/energy efficiency at fleet scale.

Economic: Integrated manufacturing plus early validation means fewer hand-offs, fewer surprises, and cleaner PPAPs, leading to lower TCO through reduced scrap, compressed timelines, and extended service intervals.

Contact us today for impact- and abrasion-resistant glazing solutions

Future Trends in Automotive Glazing & Panels

- Larger, more complex curvature enabled by formable hardcoats, expanding panoramic visibility and branded design language.

- Integrated functional stacks that combine anti-scratch, anti-fog, and IR/UV heat management to reduce HVAC loads and improve comfort.

- Data-driven maintenance using haze and wiper-cycle monitoring to replace glazing on condition, not on schedule.

- Hybrid laminates & recyclability pathways tuned to ESG targets, balancing durability requirements with end-of-life disassembly.

Five Star’s coatings portfolio, R&D customization, and large-format capacity align with these developments today, with technical data and lab programs ready to support new platform rollouts.

Frequently Asked Questions

What is the meaning of automotive manufacturing in this context?

It is the integrated design-through-production of vehicle systems—like glazing and exterior/interior panels, that meet performance, safety, and regulatory targets, now under stronger lightweighting and sustainability constraints. Five Star contributes engineered polycarbonate performance windows, Fusionite™ coatings, thermoformed plastics, and advanced composites, validated in-house.

What do automotive manufacturers do with glazing and panels?

They specify materials, shapes, finishes, coatings, and validation test plans; qualify to DOT/ANSI/ECE/FMVSS; and scale repeatable production. Five Star’s vertical integration (forming → coating → CNC → assembly → lab) and ISO 9001 quality system shorten cycles and reduce risk.

What is the automotive manufacturing process for these components?

Concept → CAD/DFM → drape/vacuum/pressure forming → CNC finishing → coating (Fusionite™) → printing/frit/etch → assembly → lab validation (optics, abrasion, environmental) → PPAP → SOP.

What’s an example of an automotive product here?

A transit bus windshield with large curvature: polycarbonate substrate, screen-printed frit, Fusionite™ CGIII ultra-abrasion topcoat (low Taber and wiper ΔHaze), anti-fog inner surface. —Validated to FMVSS 217a/ANSI Z26.1, manufactured in large format (up to ~8 × 11 ft).

At-a-Glance Specs & Signals for Evaluators

Five Star Facilities & Quality Signals

- ~350,000 sq ft across multiple specialized buildings (forming, coating, CNC, composites, finished goods) with on-site lab; ISO 9001:2015 certified through 2027.

Prototypes in ≈2 weeks post-CAD/NDA; PPAP/PFMEA support; multi-axis CNC (3/5/6-axis) and oversized ovens/molds.

Polycarbonate Windows (Performance)

- Impact: ≈200–250× stronger than glass.

- Weight: typically ~40–60% lighter than glass (design-dependent).

- Standards: USDOT, ANSI Z26.1, FMVSS 217a, ECE R43; aerospace programs aligned to AS9100.

Fusionite™ Coatings (Selected Data Points)

- CGIII: Taber ΔHaze <2% (1000 cycles); Wiper ΔHaze <2% (20k cycles).

- CGII: UV weatherability with 5-year Florida pass; ANSI Z26.1 AS5/7.

CGAF: Anti-fog meeting EN-166 N; abrasion K-mark.

Thermoformed Plastics

- Process: Vacuum (large, lightweight) and pressure forming (fine detail).

- Thickness: 0.010–0.500 in.

- Use Cases: Exterior/interior panels, bezels, enclosures where styling and cost efficiency matter.

Putting It All Together: A Practical Framework for OEM Teams

- Define the duty cycle

Capture debris profile, dust/wiper cycles, cleaners/chemicals, UV exposure, and optical criteria (transmission, haze, distortion). This informs material thickness, laminate needs, and the coating stack (abrasion class, anti-fog, UV/IR, chemical resistance). - Co-develop the part and process

Use drape forming for large curvature and pressure forming where definition and textures matter. Closely coordinate CNC edge conditions, mounting features, frits, and etching for serialized traceability. - Validate early, in-house

Taber & wiper abrasion, optical transmission/haze, environmental durability, and chemical resistance testing de-risk launch and accelerate PPAP. Five Star’s on-site lab reduces iteration time and third-party queue risk. - Scale with documentation

Lock process controls, finalize PPAP/PFMEA, and plan spares and service kits using haze/wiper-cycle condition-based maintenance thresholds where appropriate.

Build Lighter, Clearer, Longer-Lasting Platforms with Five Star

From EV delivery vans and transit buses to specialty vehicles and mixed ICE/HEV fleets, Five Star’s polycarbonate performance windows, Fusionite™ coatings, and thermoformed panels deliver measurable advantages in durability, usability, and performance—while supporting sustainability and cost objectives.

- Start faster with rapid prototypes and in-house validation.

- Launch smarter with standards compliance (USDOT/ANSI/ECE/FMVS 217a) and PPAP documentation.

- Run longer with glazing that resists impact, abrasion, UV, chemicals, and fog, reducing downtime and replacements.

Share your CAD and duty-cycle details, and the Five Star team will recommend an application-specific coating stack and forming approach tailored to your platform’s durability, optical, and cost goals.

Get your free application-specific recommendation

About Five Star Fabricating

- Founded: 1978; Facilities: ~350,000 sq ft across specialized buildings; ISO 9001:2015 certified.

- Core: Performance polycarbonate windows, Fusionite™ coatings, thermoformed plastics, advanced composites.

- Integration: Design → forming → coating → CNC → printing/etch → assembly → on-site lab validation.

Suggested internal anchors for this pillar page

- Performance Windows (Polycarbonate) — engineering criteria, thickness guidelines, mounting strategies, and caselets.

Fusionite™ Coatings Group — CGIII, CGII, CGI, CGFII, CGAF data points and selection guide.

Thermoformed Plastics — vacuum vs. pressure forming, DFM checklist, tooling considerations for 0.010–0.500 in panels. - Advanced Composites — carbon-fiber for closures, aero panels, and hybrid assemblies.

Write a Comment