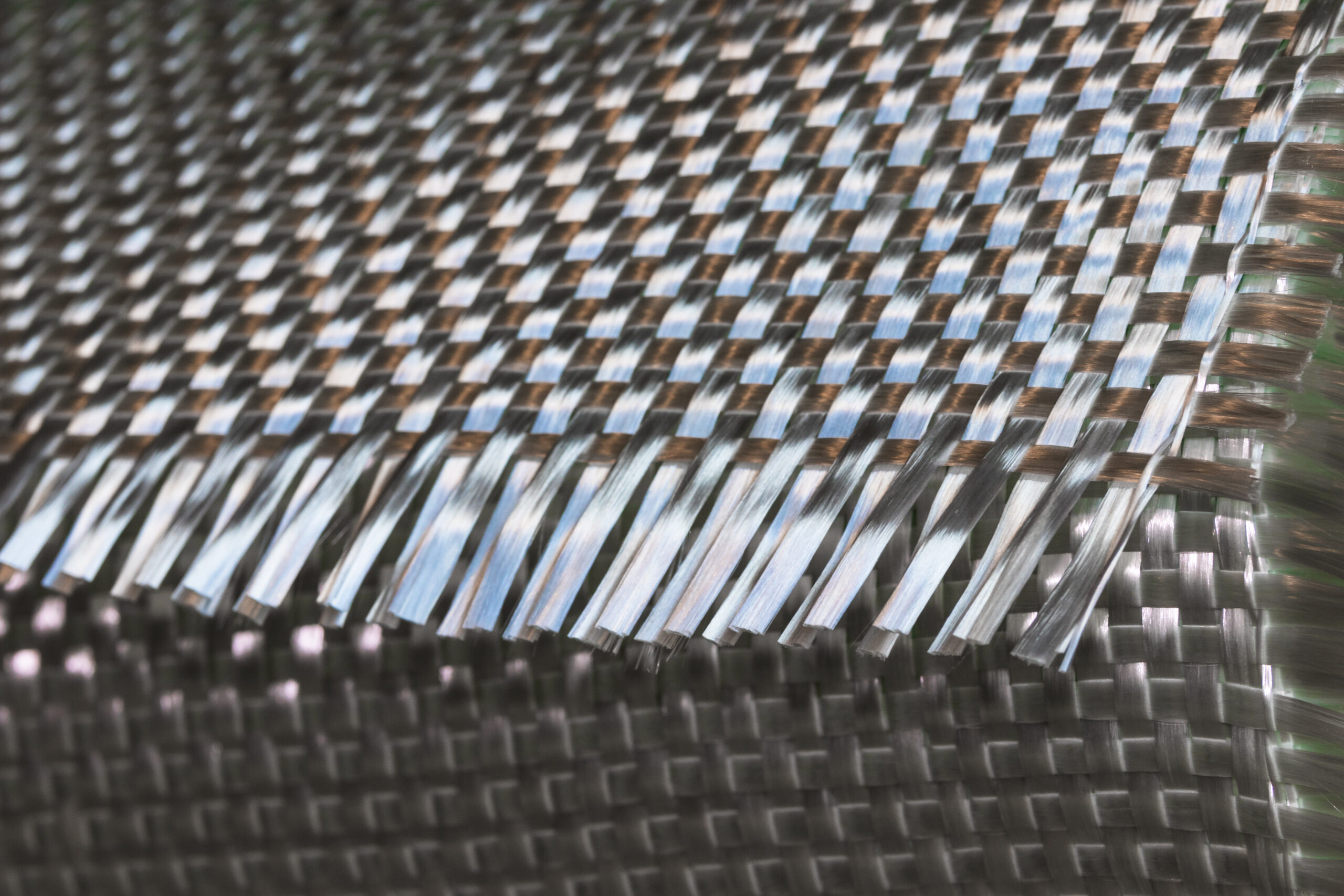

Custom-Engineered for Strength, Precision & Versatility

Five Star Fabricating, Inc. is a leading provider of advanced composite body panels and structural components, delivering high-strength, lightweight solutions tailored for high-performance industries. Our custom carbon fiber composites are engineered for superior strength-to-weight and stiffness-to-weight ratios, making them an ideal choice for demanding applications across automotive, heavy equipment, transportation, and industrial sectors.

With an in-house tooling department and advanced CNC machining capabilities, we provide precise, high-quality composite components while ensuring rapid production cycles and strict quality control. Whether you need custom composite fabrication, carbon fiber tooling, or large-scale manufacturing, Five Star Fabricating offers innovative solutions to meet your exact specifications.

Why Choose Five Star for Your Advanced Composites?

- Lightweight & High-Strength Materials – Our carbon fiber composites provide up to 70% weight reduction compared to traditional materials like steel, without compromising durability.

- Custom Composite Engineering – Tailored solutions to fit specific industry needs, from automotive body panels to composite parts for industrial applications.

- State-of-the-Art Manufacturing – Utilizing 3, 5, and 6-axis CNC machining, advanced bonding techniques, and high-precision mold tooling for superior quality and performance.

- Reliable Supply Chain & Material Sourcing – Strong relationships with leading material suppliers to ensure consistent quality and availability.

- Fast Prototyping & Scalable Production – Whether you need a prototype or full-scale production, our flexible manufacturing process ensures efficiency and precision.

Industries & Applications

Our advanced composite solutions are designed for industries requiring durability, lightweight performance, and precision manufacturing.

Automotive & Motorsports

- Carbon fiber body panels for reduced weight & improved aerodynamics.

- High-performance carbon fiber chassis components.

- Custom composite solutions for race cars & performance vehicles.

Mass Transit & Sustainable Transportation

- Lightweight, impact-resistant materials for buses, rail, and commercial vehicles.

- High-strength composite solutions for structural reinforcements.

- Durability-focused applications for public transportation safety.

Heavy Equipment & Industrial

- Structural reinforcement components for industrial machinery.

- Wear-resistant composite parts for heavy-duty applications.

- Custom-molded solutions for enhanced performance & longevity.

Material Handling & Safety Equipment

- High-strength composite solutions for protective gear & industrial safety.

- Impact-resistant materials for handling & processing applications.

- Custom-fabricated safety equipment components.

Looking for a prototype? Learn more about our engineering & design services here.

Advanced Composite Manufacturing Capabilities

Precision Carbon Fiber Tooling & Mold Production

Our carbon fiber tooling solutions ensure high-quality molds, offering dimensional stability, heat resistance, and durability. Whether you need high-performance prototypes or full production runs, Five Star delivers efficient, cost-effective manufacturing.

Multi-Axis CNC Machining for Complex Components

We utilize advanced CNC machining to craft intricate, high-tolerance composite parts with unmatched precision, ensuring consistency across large-scale production.

Custom Bonding & Fastening Techniques

Our proprietary bonding methods allow us to integrate metal fasteners, tethers, hinges, and custom reinforcements directly into composite components for enhanced durability and function.

Frequently Asked Questions (FAQs)

-

What are the advantages of carbon fiber composites?

- Carbon fiber composites provide exceptional strength, lightweight performance, and resistance to environmental factors, making them an ideal alternative to metal components.

-

How does Five Star ensure quality in composite manufacturing?

- We implement rigorous quality control measures, including precision CNC machining, material testing, and in-house tooling, ensuring superior performance and durability.

-

Can I request a custom composite solution for my industry?

- Yes! We specialize in custom composite engineering for automotive, industrial, and transportation applications. Get in touch to discuss your project requirements.

Request a Quote Today

Looking for high quality carbon fiber components? We're happy to learn more about your requirements.